Products

-

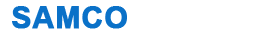

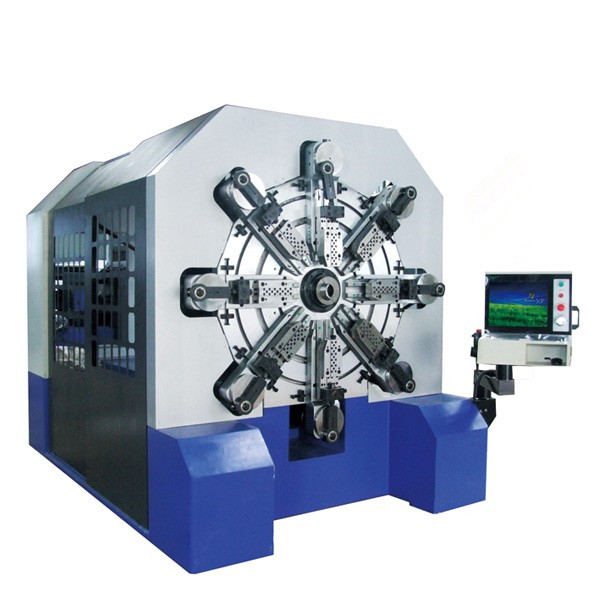

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

CNC Machine Tools (2)

The controllers have a number of modes in which they operates. There can be four possible modes in which the controller can function in relation to a machining center. The first shows a typical driling machine operation, termed as point-to-point mode. In this, the control has the capability to operate all the three axes, but not necessarily simultaneously. As a result, it would be possible to move the tool to any point(in X and Y-axis) in the fastest possible speed and carry out the machining operation in one axis(Z-axis) at that point. This would be useful for drilling and punching machines. The second type is an improvement over this in which in addition to the point to point mode, the machine tool has the capability to carryout a continuous motion in each of the axis direction. This would help in obtaining the milling in a straight line along any of the axes. The third type shows a control system, which improves the previous type by adding the simultaneous motion capability in any two axis. This is what is required in most of the cases. Any 3D profiles to be machined can be completed using the concept of 2.5D mode, in view of the limitation of the machine. The last one is the highest form of control, which is generally found in most of the current day control systems. This gives the capability of simultaneous three or more axes motion. This would be useful for machining most of the complex 3D profiles encountered in industrial practice such as aerospace components, moulds and dies.