Products

-

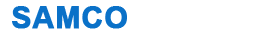

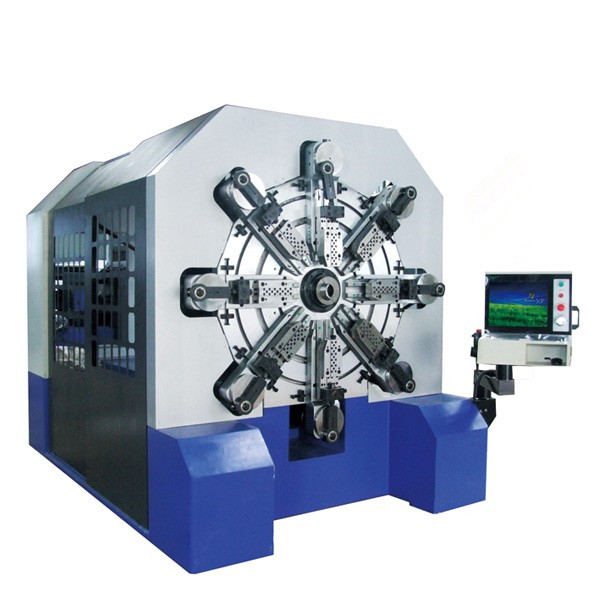

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

CNC-780-3D & CNC-7120-3D Wire 3D Molding Machine

Description:

CNC-780-3D & CNC-7120-3D Wire 3D molding machine:

Wire forming machine is made of adjusting constant speed institutions, preforming institutions and forming institutions which is setted in the base, adjusting constant speed institutions, preforming institutions and forming institutions is connected in order; Adjusting constant speed institutions is made of shell, vertical roll, plain-barrelled roll and a motor, plain-barrelled roll and vertical roll is respectively setted in pairs. Through the bearing set on the shell,on one side of each pair of roller of a roller bearing is setted adjusting bolt, on one side of each pair of roller is setted pitch wheel, on another side is setted crankset, among one of roller's crankset and the last one of roller's crankset is connected by chain, another roller's crankset is connected with next pair of roller's crankset, the most front of one pair of roller's crankset is connected with motor by reducer. Preforming institutions is made of shell, motor and a pair of cylindrical slot roller, cylindrical slot roller is fixed on the shell by bearing. Cylindrical slot roller set up extrusion slot, and one of side one cylindrical slot roller set up adjustable bolt, on the other side of cylindrical slot roller set up pitch wheel, a cylindrical slot roller's shaft connect with motor by cardan joint and reducer. Forming institutions is made of shell, planetary slot roller, bass drum and motivation components, each planet groove and by setting the bracket on the housing and arranged on the bracket which are mutually arranged 120 degrees angle of rollers and roller working face is an arc, one end of the casing setting drum, drum shaft through the reducer is connected with a motor.

Technical Paremeters for Wire Forming Machine:

Model | CNC-780-3D | CNC-7120-3D | |

Wire Diameter | Iron Wire | 3.0 - 8.0 mm | 3.0 -12.0 mm |

Steel Wire | 3.0 - 6.0 mm | 3.0 -6.0 mm | |

Maximum Feeding Length | Infinite | Infinite | |

Angle of Bending | ± 0.02° | ± 0.02° | |

Maximum Wire Feed Speed: | 70m/min | 70m/min | |

Maximum Bending Speed | 3 turns/sec | 3 turns/sec | |

Location Accuracy | ± 0.02° | ± 0.02° | |

7 Axles | Wire Feeding Servo Motor: 2.7KW; Wire Feeding Servo Motor: 4.4KW Wire-switching Servo Motor: 2.7KW; Wire-switching Servo Motor: 2.7KW Torsion Axis Servo Motor: 2.7KW; Torsion Axis Servo Motor: 4.4KW Lifting platform Servo Motor: 2.7KW; Lifting platform Servo Motor: 2.7KW Cut Axis Servo Motor: 2.7KW; Cut Axis Servo Motor: 4.4KW Torsion Lifting Platform Servo Motor: 2.7KW; Torsion Lifting Platform Servo Motor: 4.4KW Core-switching Axis Servo Motor: 2.7KW; Core-switching Axis Servo Motor: 2.7KW | ||

Installation of Electric Power | 19.3KVA | 23 KVA | |

The Machine Volume | Length 2000mm | Length 2000mm | |

Width 4100mm | Width 4100mm | ||

High 1900mm | High 1900mm | ||

Machine Weight: | 4300KG | 4600KG | |

Stardard Accessories: | |||

(1) Wire Feeding Wheel | 4pcs | ||

(2) Cutter + Cutter Fixed seat | 1 set | ||

(3) Swivel Head | 2pcs | ||

(4) Tool Cabinet | |||

Selection equipped: | |||

(1) Wire feeding frame 500KG, 1000KG or 1500 KG | |||

(2) Tools (3.0/3.5/4.0/4.5/5.0/5.5/6.0/6.5/7.0) | |||

Part of Samples Show: