Products

-

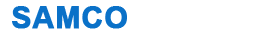

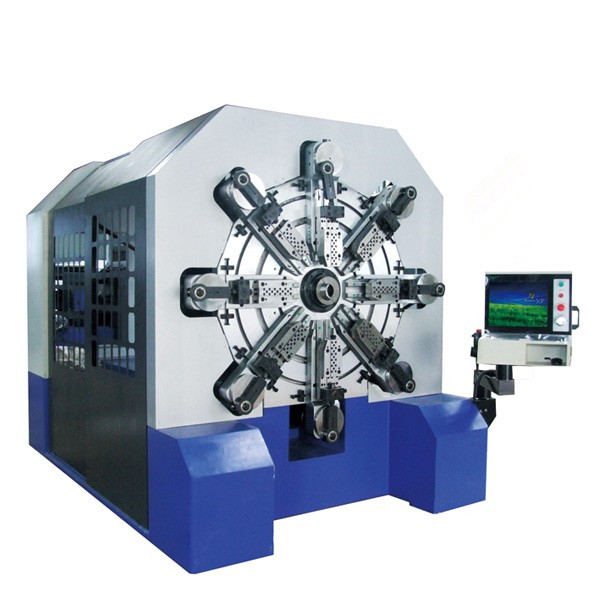

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

CNC Machine Tools (1)

At present, CNC machining center appears to be the most capable and versatile automatic machine tool that can perform drilling, tufting, milling, boring, reaming and tapping operations. The general objective behind the development of CNC machine tools continues to remain the reduction of cost of production by reducing the production time. This in turn is directed towards the avoidance of non-productive time which is mainly due to the number of setups, setup time, work piece handling time, tool change time and lead time. The performance of a variety of machining operations on the same machining center eliminates the non-productive waiting time that occurs if such operations are performed on different machines. Provision of automatic tool changing, indexing of tables and several pallets add to the productivity of the machining centers. The basic information that has to be input into the system consists of the part geometry and cutting process parameters followed by the cutting tools used. This part program is then entered into the controller of the machine, which in turn runs the machine tool to make the parts. The command received from the operator is communicated to the corresponding axis driving system for execution. The axis motion control system operates in a feed back loop with suitable transducers such as linear scales and/or rotary encoders to get the appropriate position or velocity feed back. Most of these systems have a very high response with good resolution of the order of 1 micron or less.